Description

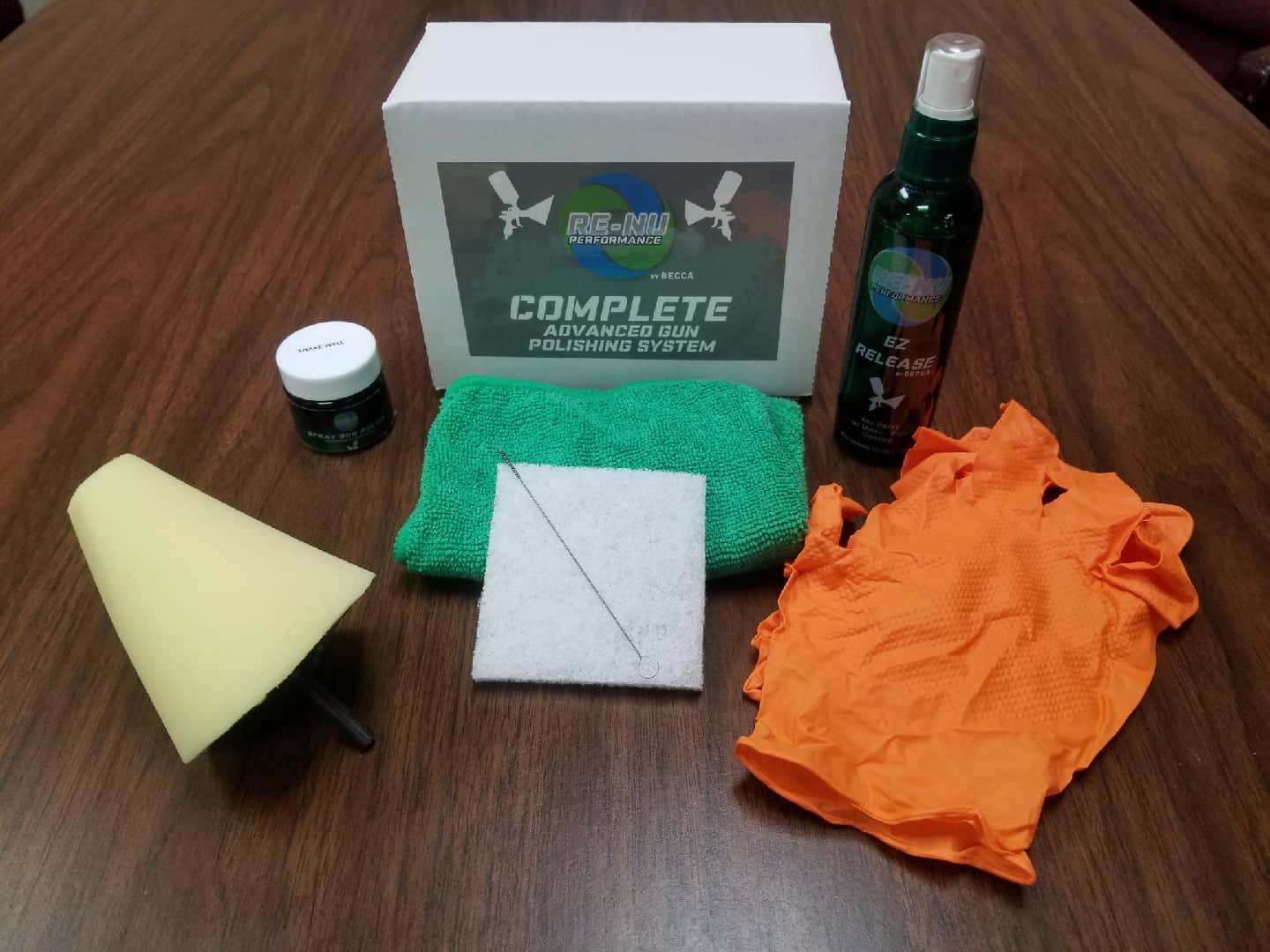

BECCA’s Re-NU™ is the first Spray Gun Polishing System on the market that will remove/reduce paint materials and micro inclusions from the surface. This will provide less friction and turbulence in the flow of fluid and air to maximize performance! The system is a 4 step process:

Step One: Tear Down

Tear down the spray gun completely. This includes fluid and air passageways

Step Two: Detail Cleaning of the Spray Gun

The spray gun should be completely dis-assembled to assure removal of all residues.

We recommend the use of:

WATERBORNE COATINGS – Acetone or Acetone mixed w/ Aircraft Stripper 10:1 ratio

OTHER COATINGS – Solvent of choice or Solvent of choice mixed w/ Aircraft stripper 10:1 ratio

Clean all parts including fluid and air passageways

Step Three: Re-Nu Polish

Apply Re-Nu polish to all surfaces of the spray gun and its parts. Make sure to focus on the needle and the fluid tip. Do not let the polish dry completely before removing w/ the microfiber cloth. We have supplied a special brush to polish the inside passageway of the fluid tip. Polish…wipe/rinse the brush…repeat this process 2-3 times. Remove the polish residues with the supplied microfiber cloth.

Step Four: EZ Release Spray (for Waterborne & Solvent)

Apply EZ Release w/ Micro-Film coating to all surfaces including air and fluid passageways. The micro-film coating is PH neutral and will minimize corrosion and will prevent paint from adhering to the surface. Re-apply after cleaning the spray gun during normal production.

Reviews

There are no reviews yet.