Do you struggle with Body Shop Material Profit? We hope these 4 steps will help.

Step 1 – Body Shop Material Profits – S.O.P. and Creation of the A.P.L.

Work with Your technicians to create an SOP for common operations performed inside your shop. Operations like panel preparation, Plastic Filler Application, Primer Application or Adhesive Application are all examples of tasks that are repeated daily in your shop. Your SOP should contain all the products used in these operations.

Instituting an A.P.L. = Body Shop Material Profits

The SOP will call out Your Approved Product List (A.P.L.) The A.P.L. should only be changed when your employees agree that there are new products that outperform your current items. Don’t allow vendors to pop in, distract production and leave samples that may tempt your technicians to “just order a box or 2”. This leads to increased inventory levels and waste.

Train Your Vendors

Your vendors should present solutions to the group for discussion at specified training events like “Lunch and Learns”. After this step is complete you will probably realize that you have twice as many products in your shop as you need. Furthermore, systematically consume all products that aren’t on your new A.P.L. and do not reorder them.

Step 2 – Body Shop Material Profits – Point of Use Carts

The second step to Body Shop Material Profit is to work with your technicians to discover how products are being used in the shop. You will discover that certain products are used in groups to perform common operations.

Using Point of Use Carts = Body Shop Material Profits

Group these products onto “Point of Use Carts“. If Point of Use Carts are implemented correctly, each technician will no longer need to have his own stock of every item you purchase.

Common Point of Use Carts are Filler Application/Prep Carts, Paint Prep Carts, Primer Carts, Masking Carts, Glue Carts, Sanding Carts or Detail Carts. Carts should be carefully thought out to remove horizontal surfaces because they hold litter that create disorganization. Your carts should visually demonstrate where products should be placed so that it’s obvious where everything goes and what is missing. At the end of this process, you will realize that you have 5 to 10 times more inventory than you need.

Organized Body Shop Cabinet

Unorganized Point of Use Cart

Better Point of Use Cart

Best Point of Use Cart

Step 3 – Body Shop Material Profits – Set Goals

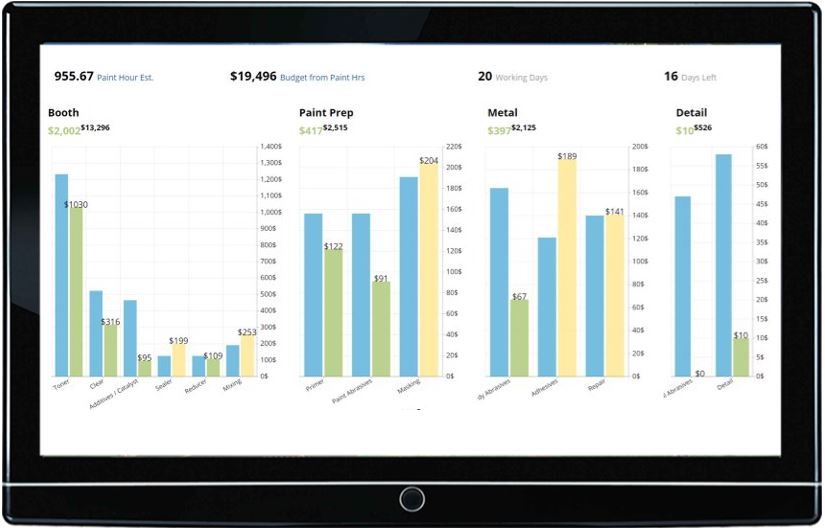

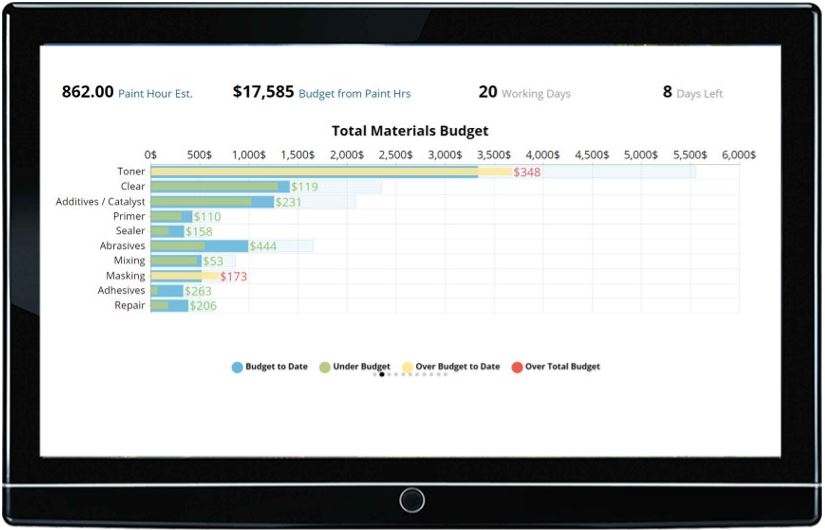

Measure and post your Body Shop Material Profit Performance regularly. There are some great Inventory Control Systems in the market that will assist you with this. Be very careful the metrics you pay attention to related to Body Shop Material Profit.

There are 2 parts to understanding the metrics that are important regarding Material Profit.

Step 3 – Part 1. Ask yourself, “How do I get paid for Paint and Materials?”

In most shops materials are sold on the estimate by a Material Rate that is applied to each hour of Refinish labor. Look at how you sell materials and you’ll quickly realize that metrics like expense to sales ratio are meaningless. If materials were sold based on your gross sales, expense to sales would be a valid metric. Variation in part prices and sublet operations change the sales mix, so using gross sales as a guide for material profit is about as accurate as predicting your net profit using the same method.

Controlling Cost Per Refinish Hour = Body Shop Material Profits

Since materials are sold by the refinish hour, the only true metric is “Cost Per Refinish Hour” (CPRH). Pay attention to your Cost Per Refinish Hour, Sale Per Refinish Hour (Up Next) and your average paint hours per Repair Order. Don’t listen to other shops or trade magazines either, focus on bettering your own numbers tracked the same way each month.

Let’s do Math. My Paint Bill is $10,000.00 this month. This month my paint shop produced 660 Paint Labor Hours. My Cost Per Hour is $15.50.

Shops do not realize how their money is spent on Paint and Materials. Based on our research the normal distribution for material usage looks like this.

% Product Cost Per Hour Notes.

11% Clear Coat $1.70 CPRH Why do shops think they spend the most of their money on Clear?

30% Color $4.65 CPRH Focus your efforts on controlling this. Look at reasons for high color usage.

12% Catalyst $1.86 CPRH Control Clear and Primer usage. Mix accurately.

7% Primer/Sealer $1.08 CPRH Cheaper Primer does not move the needle. In fact if it causes rework it’s really bad.

3% Solvent $0.47 CPRH Cheaper solvent is not the answer.

10% Abrasive $1.55 CPRH Minimize Grits and types in use, use Point of Use Carts.

10% Masking/Mixing $1.55 CPRH Take a hard look at Disposable Cups and Tape. Check Out The Tape Thing

7% Repair Products $1.09 CPRH Cheaper Filler isn’t the answer

10% Miscellaneous $1.55 CPRH Minimize extra items laying around. Bill for things like cavity wax!

_________________________________________________________________________________

100% $15.50

Step 3 – Part 2. Ask yourself, “What drives material sales?”

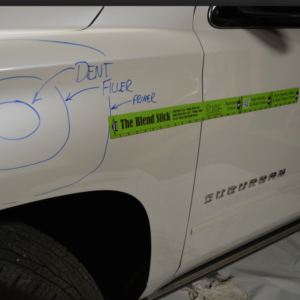

As previously discussed, Paint Hours drive Material Sales. If you increase paint hours you increase sales which increases your material profit. Look for every opportunity to capture every possible refinish hour. What is your policy on blend panels? Collision Edge makes a product to help with that, Check out The Estimating Kit. There are a lot of other P-Page items that will certainly benefit your estimate and make for safer repairs. Check out Collision Hub Estimate Training.

Body Shop Material Profits – Let’s do the math.

I sold $16,000 in Materials on my estimates in this same month. Is that a good number?

Let’s do the math. $16,000.00 divided by 660 Hours is $24.24. Material profit for the month is 36%.

OK good, but what did you leave on the table in material sales? If your material door rate is $30 and your Sale per hour is 24.24, you left $5.76 on the table.

$5.76 X 660 hours is $3801.60 per month or $45,619.20 annually.

Do you see how this could affect Your Net Margin?

So what happened?

Look at your closed estimates. You will find leaks related to things like random material caps or in some cases money being moved out of materials to cover parts or additional labor that wasn’t caught on the original estimate. Often times it’s easier for an estimator to take money from materials to avoid having to do that 2nd or even 3rd supplement. Try to catch these items in your repair plan.

Step 4 – Body Shop Material Profits – Optimize your Processes and Equipment.

Pay close attention to the materials that you use and even closer attention to “how” they are being used and the equipment involved in the process. Look at all things related to air and the process of getting your products on the repair. You may want to reference our E-Book entitled “Air is Free but Could Cost You Thousands”. This Free E-book takes a deep dive into air from the compressor all the way to the spray gun.

Look at Your booth.

Go take a picture of your booth and compare it to how booths look new on the internet. You see many times we cannot see inside our own 4 walls until we look. Take inventory of the dirt control measures used in your shop. Document the Standard Operating procedure you will follow to minimize trash. We see several regular examples of skipped operations and maintenance items like pre-wash, post disassembly wash, sanding pre-clean(a big one for abrasive life), dust free sanding systems (also helps abrasive life and trash control), Static Free Spray Suits, gun maintenance, hose maintenance, Personal hygiene and the list goes on.

Don’t be afraid to spend money on products like 3M Dirt Trap , New Pig Floor Covering, or Crash Wraps Wall Film

We have found that most trash that ends up in the panel came from either the car, the booth floor(Not the walls) or the painter. Paint imperfections are the number one killer of Body Shop Material Profit.

We published a free tool called My Maintenance Tracker to organize your efforts in tracking items that are commonly forgotten. Feel free to download and edit your copy, if you need help reach out to us on Facebook or Instagram. @CollisionEdge

You may also want to check out another one of our post called “Bad Primer or Bad Process”.

Let’s summarize the Body Shop Material Profit discussion.

We hope this all makes sense.

Minimize Products in use. Make product choices a very serious matter. Minimize open inventory. Pay attention to maintenance and processes. Track your numbers and don’t be afraid to buy from a quality distributor that can help you with your material profit. Expect to pay a premium for someone who is going to help you minimize waste and maximize profits. Focus on these numbers, Cost Per Refinish Hour, Sales Per Refinish Hour and Average Refinish Hours per Repair Order.

Consider this, what is the difference in finding a good jobber consultant and the money that you pay your finance guy to maximize your investment earnings? If you work with quality people the profits will outrun the cost every time.

We hope you found this beneficial. Again, Give us a follow on Facebook, Instagram and You Tube. @CollisionEdge

We appreciate your time.

Tim Briggs Ginger Briggs

Tim@CollisionEdge.com Ginger@CollisionEdge.com

Have your friends Sign up for Our Mailing List!

Check out some of our other Post!

Replace Your Windows with Doors