What price will you pay?

by Tim Briggs

CollisionEdge.com

Collision Edge is committed to solving problems for the Collision Repair Market.

Visit our websitewww.collisionedge.com

Body Shops are dirty places, but they don’t necessarily have to be. In a day when body shop margins are having the life squeezed out of them, it’s extremely important to eliminate waste everywhere possible. As it turns out, sanding dust is a huge source of waste.

The only way to remove this waste is vacuum assisted sanding. For many years companies have promoted expensive whole shop systems that were never used because the system manufacturers never understood how technicians work in body shops. Today’s Vacuum sanding systems offer mobility and affordability that can no longer be ignored. There are several quality systems offered to the industry. In this recent experience, we reviewed the MIRKA Sanding System complete with their electric Orbital DA and Orbital Block, but there are other strong contenders like 3M Festool , the Dynabrade Mini Raptor and Uniram Dustless Sanding Vacuum. The new electric tools offered by many of these companies are far superior to their pneumatic counterparts due to largely to size, weight, and versatility. The benefits are compounded by energy efficiency and convenience.

It is shocking how much dust is generated inside of a body shop. In this example, we measured 8 lbs of sanding dust created from a single large job. Based on some simple math and depending on your work mix, it’s probable that your technicians produce 3-8 lbs of sanding dust per week.

Many of you are thinking “so what?”, “that’s the way it has always been”, “we just have our detail guy clean it, we do it on every job.” A deeper dive into the true cost of dust will reveal many things the “traditional Body Shop” has never realized.

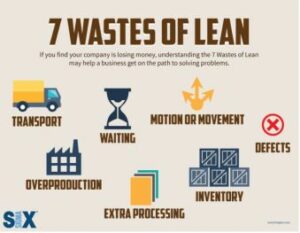

The cost of dust can be summarized in a handful of ways.

Everyone sees the first and most obvious waste is the cost of cleaning the car. However, the biggest and most critical impact is to the health of your employees. Other significant factors are the labor associated with paint finish correction, material consumption, and environmental impacts.

Let’s start with the cost to clean the car. It’s really not about the amount you pay your detail technician. It’s more about the opportunity to deliver more cars because your shop is reducing “defect” waste on each job. On Friday when you are trying to deliver all of your cars, (a problem for another day) how much easier would it be if each job was simpler to process. Most shop owners will say “my people are careful with car interiors” but the impact is unavoidable. Dirty shops equal dirty cars. Dirty cars equal missed delivery opportunities.

Let’s start with the cost to clean the car. It’s really not about the amount you pay your detail technician. It’s more about the opportunity to deliver more cars because your shop is reducing “defect” waste on each job. On Friday when you are trying to deliver all of your cars, (a problem for another day) how much easier would it be if each job was simpler to process. Most shop owners will say “my people are careful with car interiors” but the impact is unavoidable. Dirty shops equal dirty cars. Dirty cars equal missed delivery opportunities.

What is the cost to your technician? Sure they wear Personal Protection Equipment, but why expose them to lethal doses of chemically laden sanding dust hoping that they are adequately protected? Vacuum systems eliminate many of the risks your employees face daily.

Let’s move on to the paint finish. Sure the painters should thoroughly clean the car in prep, but why do we send the contamination created by the body technician to the paint shop? Have you ever thought about the cost of removing trash from a panel? It is shocking to really understand the impact of trash removal on cycle time, material cost and labor. Lay a $20 bill on every piece of dirt that comes out of the booth in your clear coat and you have only begun to understand the cost of trash created by a dirty shop environment.

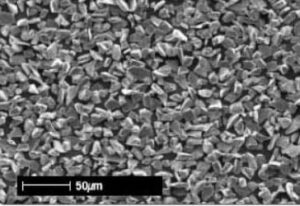

How can vacuum sanding reduce material consumption? We have already covered the detail material waste, but an even greater opportunity lies in abrasive consumption. We have studied this first hand, abrasives are typically 10% of any shops material bill. Cheaper paper isn’t necessarily the answer to this problem. Abrasives are made up of a backing material, adhesive, mineral and a top lubricant that prevents contaminate loading. This lubricant reduces friction and heat. Vacuum sanders remove dust as it is created and continually passes air over the abrasive. Cooler working temperatures lead to extended resin life subsequently extending your abrasive life. In short, heat is the enemy of sandpaper. Vacuum sanding extends the life of your abrasives.

How can vacuum sanding reduce material consumption? We have already covered the detail material waste, but an even greater opportunity lies in abrasive consumption. We have studied this first hand, abrasives are typically 10% of any shops material bill. Cheaper paper isn’t necessarily the answer to this problem. Abrasives are made up of a backing material, adhesive, mineral and a top lubricant that prevents contaminate loading. This lubricant reduces friction and heat. Vacuum sanders remove dust as it is created and continually passes air over the abrasive. Cooler working temperatures lead to extended resin life subsequently extending your abrasive life. In short, heat is the enemy of sandpaper. Vacuum sanding extends the life of your abrasives.

Finally, and most notably, what is the impact on our environment? Recent surveys indicate the number of Shops in the United States has surpassed 40,000 locations. We can argue exact numbers, but if the average shop has roughly 4.7 technicians producing even 5 pounds of sanding dust per week it quickly adds up to 48.8 Million pounds of uncontrolled pollution. In rough approximation based on our sample, the waste the Collision Industry generates could easily fill 236 railroad cars on an annual basis. -TB

Finally, and most notably, what is the impact on our environment? Recent surveys indicate the number of Shops in the United States has surpassed 40,000 locations. We can argue exact numbers, but if the average shop has roughly 4.7 technicians producing even 5 pounds of sanding dust per week it quickly adds up to 48.8 Million pounds of uncontrolled pollution. In rough approximation based on our sample, the waste the Collision Industry generates could easily fill 236 railroad cars on an annual basis. -TB

If you like what you’ve seen here today, let us know. If you are interested in information about sanding systems email tim@collisionedge.com or visit us at www.collisionedge.com or find us on Instagram of Facebook. Thank You for your support.